Projects : Tekla

Your Trusted Structural Steel Detailing Company for Tekla-Driven Projects

Project Synopsis

As a leading structural steel detailing company, Adept Engineering Solutions leverages advanced 3D modelling in Tekla Structures to deliver fabrication- and erection-ready shop drawings, connection design, erection sequencing and coordination packages for steel fabricators, erectors and general contractors.

Why Steel Fabricators & Erectors Choose Our Services

- Fabrication-Optimised Detailing: We apply fabrication logic (piece marking, nesting, CNC control, sequence planning) so that material hand-off from detailing to shop is seamless and meets your shop flow.

- Erection-Friendly Coordination: Erection drawings and connection packages incorporate anchor bolt plans, erection tables, splices, field fit-up tolerances and slab/roof interaction considerations — essential for erectors to maintain schedule and safety.

- Code-Compliant Connections: Using AISC connection provisions and tables, we detail plate, weld and bolt configurations in line with ‘Requirements for Connections’ guidance from AISC, ensuring that the chain of design-to-detailing is robust.

- Detailing Standardisation: Our drawing room implements NISD-based check-lists and conventions (sheet numbering, revision control, part lists, RFI logging) which enhances communication among designer, detailer, fabricator and erector.

Key Technical Services Offered

- 3D modelling of structural steel frameworks in Tekla including beams, columns, bracings, trusses, stairs and miscellaneous steel.

- Shop-drawing production with full detailing of bolted connections, welded connections, stiffeners, base plates, splice plates and epoxy anchors.

- Fabrication data including material take-offs, member lists, CNC export (DSTV/NC) and painting/galvanising notes.

- Erection drawing sets: anchor bolt positioning, erection sequence charts, erection bolt/weld summaries, temporary bracing and site coordination drawings.

- Connection design support aligned to AISC tables and documentation adequate for review by engineer-of-record or third-party.

- Coordination with other disciplines (concrete, mechanical, architectural) using model federation and clash detection – reducing onsite fit-up issues and RFIs.

Dust Collector

Location : AHAMADABAD, India

ROCK RECLAIM CONVEYOR

Location : TX, USA

Raw Coal Screen Chute

Location : VA, USA

SUGAR HOUSE

Location : AHAMADABAD, India

NEW MOFUSSIL BUS TERMINUS

Location : TX, USA

DSD SCHOOL

Location : VA, USA

AUDITORIUM AT VASTRAL

Location : AHAMADABAD, India

TOWER SCREENING BUILDING

Location : TX, USA

PRIMARY UNIT

Location : VA, USA

REFUSE BIN

Location : PA, USA

SCREEN STATION

Location : KY, USA

STACKOUT CONVEYOR

Location : GA, USA

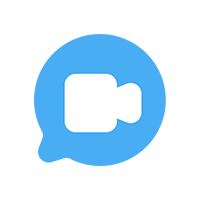

SURGE HOPPER

Location : KY, USA

CONVEYOR

Location : GA, USA

TRANSFER TOWER

Location : ABU DHABI

COURT HOUSE

Location : CA, USA

WASH STATION

Location : NC, USA

SCHOOL OF MUSIC BUILDING

Location : IL, USA

BRIDGE

Location : CA, USA

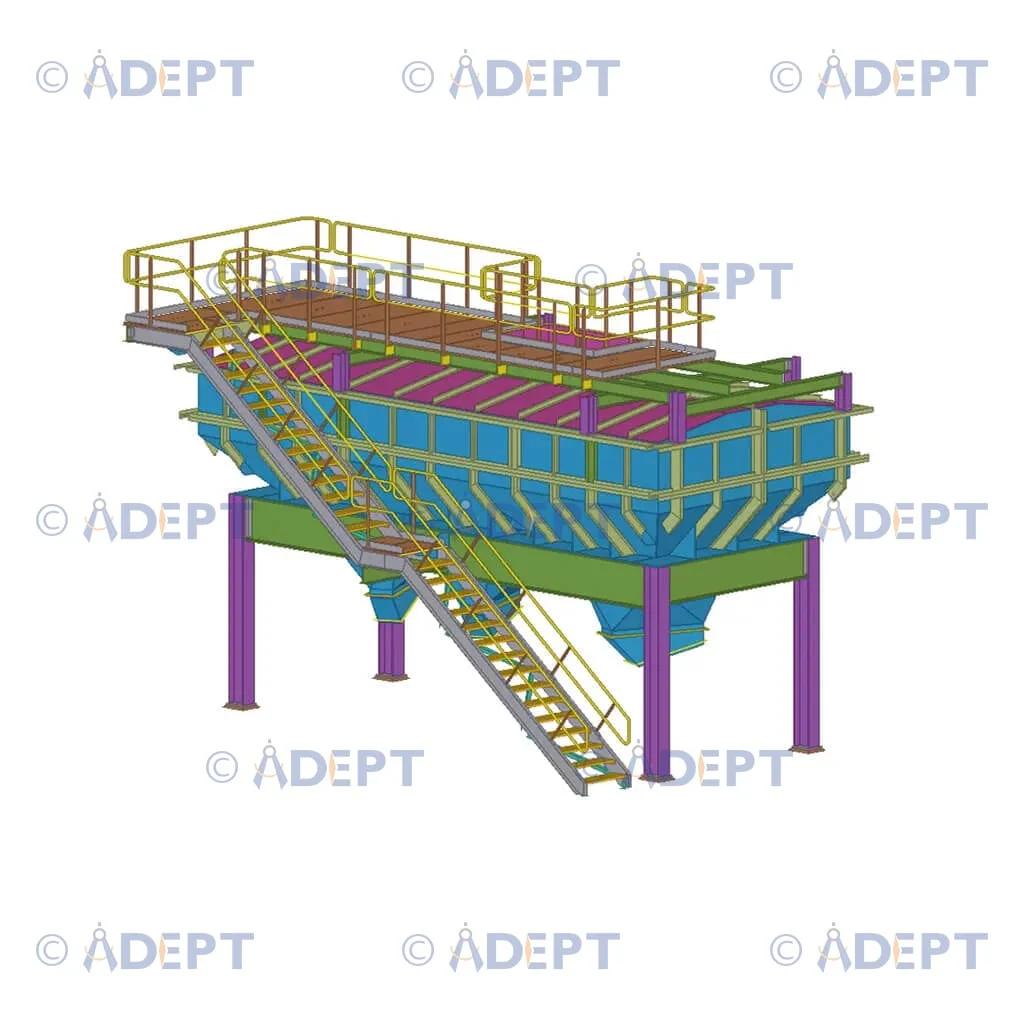

NEW PRIMARY AND FINISHING PLANT STATION

Location : SC, USA

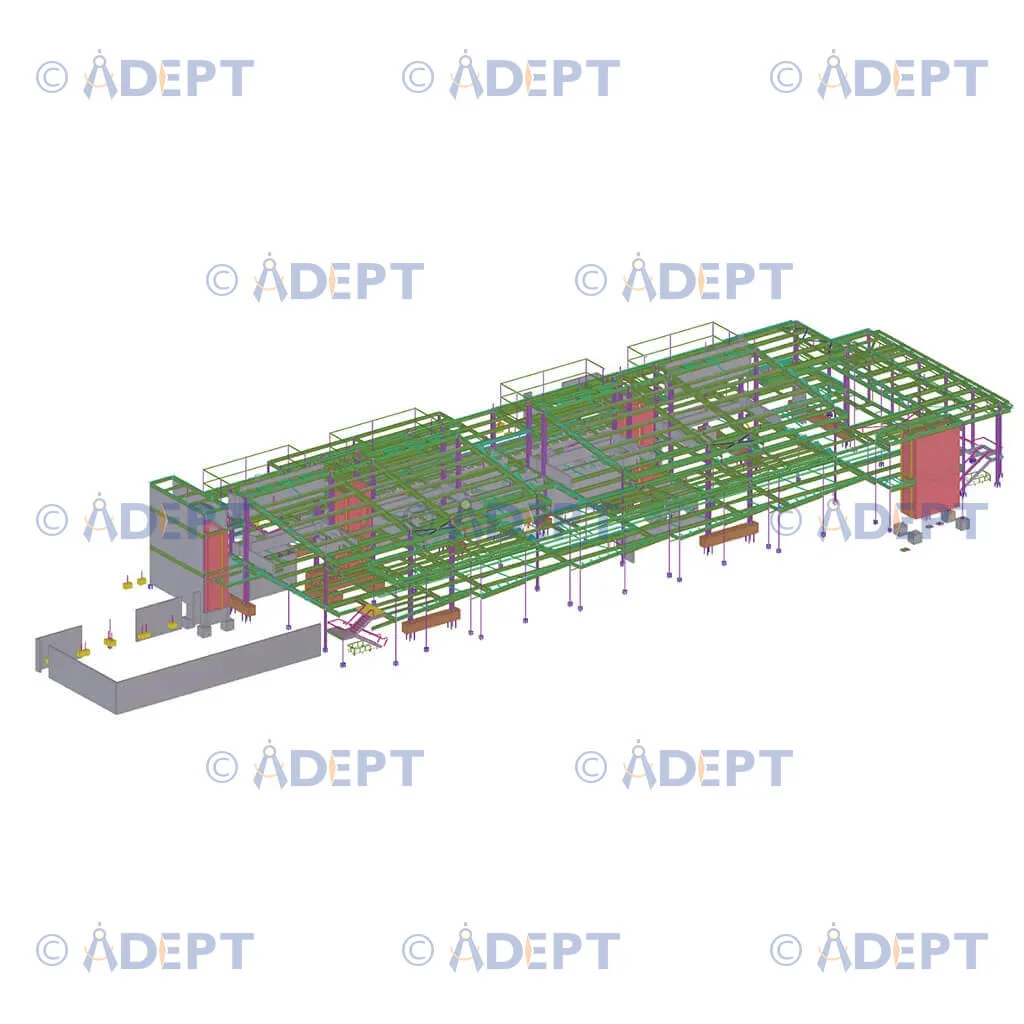

CLARIFIED WATER TANK

Location : FL, USA

Iron Ore Conveyors and Transfer Tower

STOCKPILE CONVEYOR

Location : GA, USA

40 FEET DEAIRATION TANK

Location : FL, USA

24″ CONVEYOR -SOLIDS HANDLING SYSTEM

Location : GA, USA

DIVERTER GATE

Location : OH, USA

SOLIDS HANDLING SYSTEM

Location : GA, USA

60″ CONVEYOR

Location : QUEBEC,CANADA

Project Value to Fabricators / Erectors / Contractors

- Schedule Adherence: By releasing fabrication-ready drawings earlier via BIM workflows, our clients reduce lead-time between detailing and shop fabrication, and minimise erection delays.

- Cost Efficiency: Standardised detailing practices, automated drawing productions and well-coordinated models reduce error, rework, shop spares and field corrections — hence lowering overall steel package cost.

- Risk Mitigation: With AISC- and NISD-compliant detailing and communications, our clients face fewer RFIs and erection impediments, improving project safety and client satisfaction.

- Transparency & Coordination: Detailed models and shared drawing sets mean fabricators, erectors and contractors have clear visuals and data to coordinate across disciplines, shipments, field logistics and erection sequences.

Engage Us for Your Next Steel Frame Project

If you are a steel fabricator, erector or main contractor looking for a qualified structural steel detailing company that uses Tekla for end-to-end detailing (model → shop drawings → erection packages), reach out to Adept Engineering Solutions. We support heavy industrial steelwork, commercial and civil projects and ensure your steel detailing workflow aligns with global best-practice standards (AISC, NISD) and meets fabrication and erection realities.