In the Industry if we want to excel, we should have in depth knowledge which helps us to provide solution for any type of problems. ADEPT believes the information is wealth, knowing right information at right time helps us to make decision easier and faster.

We know the connections are the heart of any structures, in which bolted connections are preferred a lot. Connection failure leads to a catastrophic failure of the structure hence connection design is very essential next to member design as it directly influences the 3M (Man, Material, Money), the optimized connection saves you lot of time also can complete your project earlier.

ROLE OF BOLTS

One of the principle fastener using in steel structures is bolt. It is manufactured item, they are installed using simple equipment, and installation and inspection can be done by persons with only a relatively small amount of training.

BOLT CODES

Specifications for materials and properties are published by ASTM. Standards for dimensions and tolerances are issued by the ANSI in cooperation with ASME and IFI. AISC manual also provides specification requirements & other design considerations for structural connections.

TERMINOLOGY OF BOLT

THINGS TO KNOW WHILE DESIGN BOLTS

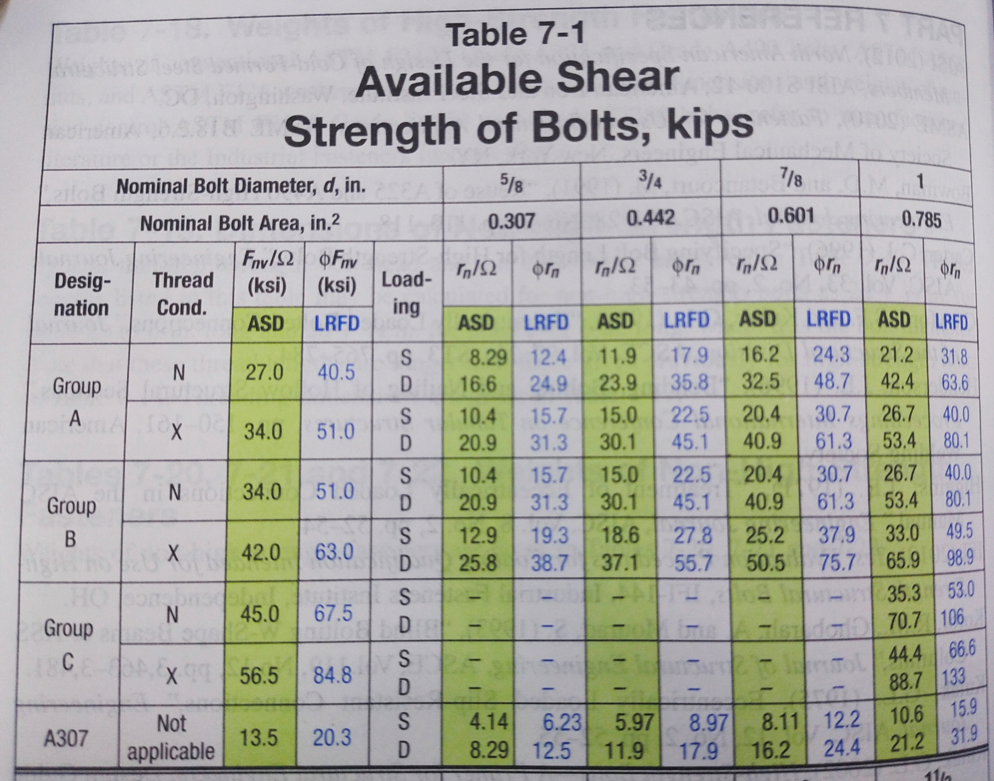

- Shear plane is the common surface between connected materials based on the number of connecting parts the shear plane numbers vary. If the threads are included with shear plane (N type) the bolt bear the strength under bolt net area, if the threads are excluded with shear plane (X type) the bolt bear the strength under bolt gross area.

- A325T bolts stands the full length threaded bolts, the bolt length less than or equal to the four times the bolt diameter only.

- A307 Bolts tensile capacity is 45 ksi most of the cases it used as erection bolts in steel structures.

- 15th Edition of AISC Manual introduced the Group C bolts such as F3043 for tension control bolts and F3111 for conventional High strength bolts.

- Slip critical bolted Connections used only when joints are subjected to fatigue loads or Joints that used oversized holes.

- 15th Edition of AISC Manual the nominal bolt hole for 1 inch diameter of bolt get revised as the (d+1/8) rather than (d+1/16)

- Pre-tensioned bolted connections used only when joints are subjected to vibratory loads.

- Bolt Diameters limited to 1 inch due to the commonly available bolt installation equipment’s designed for that capacity. Special equipment’s required for larger diameter of bolts.

- To prevent the nut from loosening the threads can be spiked or marred or the nut can be tack welded to the base metal.

- Bevel washers are required to provide when the head and nut bear have a slope greater than 1:20 with respect to the plane normal to the bolt axis.

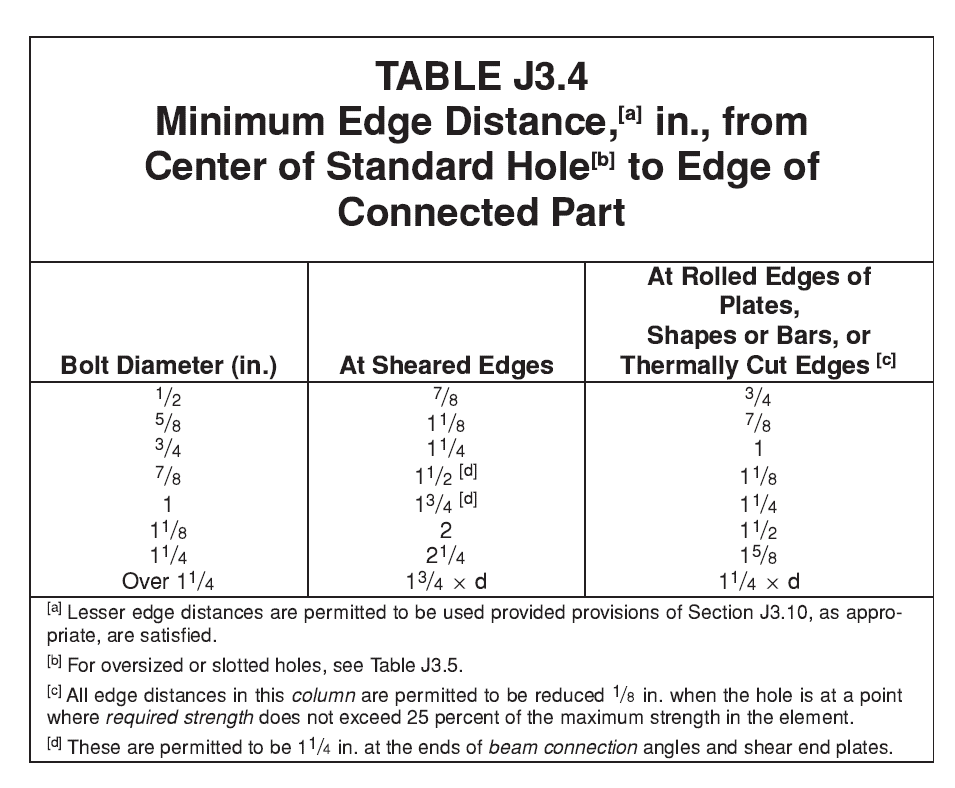

- 13th Edition the Minimum Bolt Edge Distance is dependent to material cut such as thermal cut, sawed and sheared edges in such way limitations to edge distance were made accordingly.

- Updated 14th and 15th edition the edge conditions have been grouped, meanwhile made the limitations that prevents exceeding the bearing and tear out limits on minimum edge distance and it has met for all bolt holes.

- 15th Edition of the AISC Manual provides the shear strength of bolt Group C in addition to the Group A and Group B

- Minimum spacing between the bolts should not be less than 2 2/3 times of nominal diameter of bolt, three times the nominal diameter of the bolt preferred.

- Maximum bolt spacing of painted condition the bolt spacing limited to 12 times the thickness of thinner part or 12 inches. If unpainted condition the bolt spacing limited to 14 times the thickness of thinner part or 7 inches.

REFERANCES

- AISC DESIGN GUIDE 17 – High Strength bolts – A Primer for Engineers

- AISC STEEL CONSTRUCTION MANUAL 13TH EDITION

- AISC STEEL CONSTRUCTION MANUAL 14TH EDITION

- AISC STEEL CONSTRUCTION MANUAL 15TH EDITION

CLIECK HERE TO CHECKOUT

How ADEPT so far deals with Bolted connections we have good experience in shear, axial and moment connections of commercial projects. Click here to check ADPET projects ………Read More